Precision‑engineered power‑train parts, delivered at start‑up speed.

CTA buttons: Get an Instant Quote | Talk to an Engineer

Trust metrics strip (icons + figures)

- 12 + years of OEM/ODM know‑how

- ±0.05 mm CNC accuracy

- 5,500‑machine production network

- Complaint rate of just 0.011%

Why Partner With Us

One‑stop sourcing across machining, forging, casting, stamping, and 3D printing

Digital speed – quotes in 24 h, drawings reviewed in 1-3 days

German‑style QA with ISO‑based inspection and full test certificate, matching market leaders’ promises

Surge capacity via 5,500 audited machines worldwide

We speak the language of industrial equipment manufacturing—tight tolerances, short lead times, and no excuses.

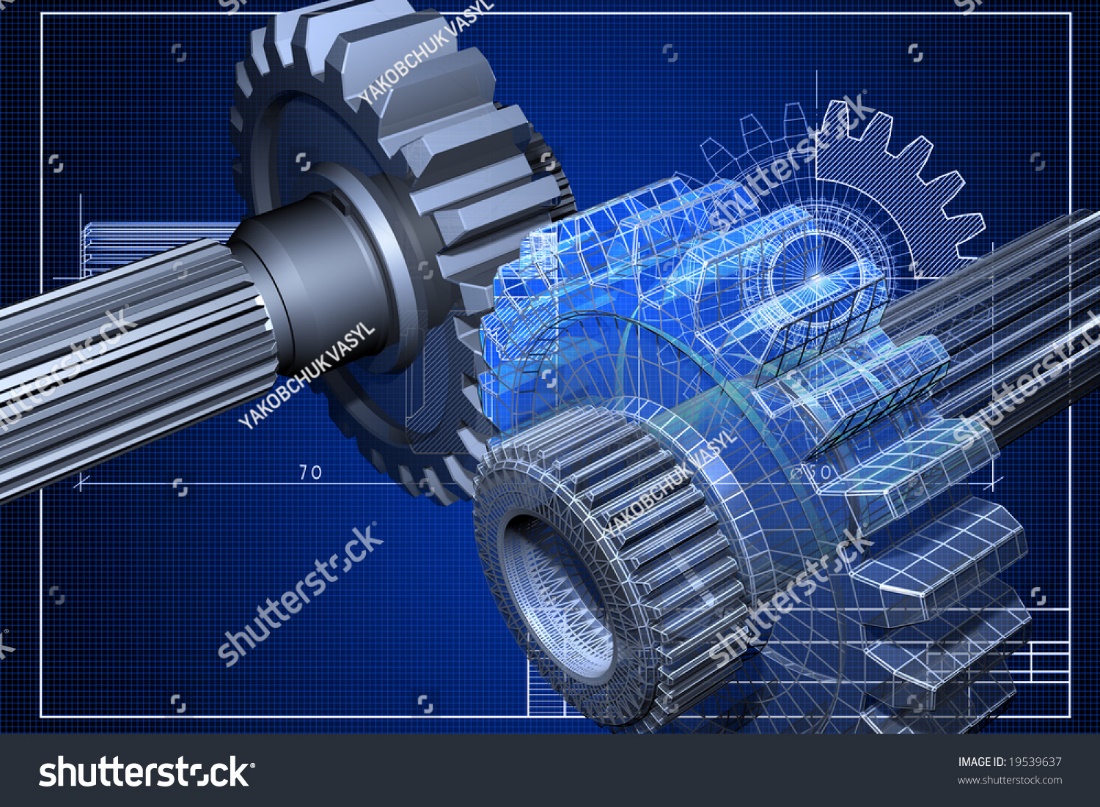

Component Focus

Image Link: https://www.shutterstock.com/image-photo/special-nut-purpose-construction-industry-light-1681643179

| Component | Typical Specs | Finishing Options |

| Gears | Spur, helical, worm · Module 0.5‑12 · Ø ≤ 600 mm | Hobbing, grinding, nitriding |

| Shafts | Length ≤ 1.5 m · Ground to Ra 0.8 · Splines/keyways | Hard chrome, black oxide |

| Custom Fasteners | Specials in alloy steel, titanium, brass | Zinc‑nickel, passivation |

All three families can be combined into custom industrial machinery components—gearboxes, couplings, or bolted assemblies—delivered line‑ready.

Manufacturing Capabilities

Image Link: https://www.shutterstock.com/image-photo/multi-tasking-cnc-lathe-machine-swiss-2498726637

- CNC turning & milling (±0.05 mm) for prototypes and serial runs

- Dedicated gear‑hobbing & form grinding cells for DIN/AGMA classes 6‑10

- Net‑shape forging/casting for large modules, followed by precision machining

- Sheet‑metal & stamping for flanges, guards, and housings

- Additive & mold tooling for rapid jigs and fixtures

Lead‑time ladder: sample 5 days ▸ standard lots 15‑20 days ▸ bulk 40‑45 days

Material Portfolio

Metals – Brass, bronze, copper, aluminum, free‑cutting & stainless steels, zinc & magnesium alloys, and titanium

Non‑metals – Nylon, POM, ABS, PP, PTFE, engineering rubbers, and graphite

Exotics (Inconel, Hastelloy, tool steels) available on request.

Design‑for‑Manufacturing Support

Upload your drawing, and our engineers return DFM feedback—cost‑down material or geometry tweaks—within 1-3 working days.

Quality Assurance & Certifications

- ISO 9001‑2000 certified workflow with incoming, in‑process, and 50% final sampling

- Lab tools: optical metal analyzer, Rockwell hardness, 2D CMM

- Test certificate shipped with every batch, which represents the sector’s best practice

Assembly & Value‑Added Services

Image Link: https://www.shutterstock.com/image-photo/close-gear-black-white-filter-concept-2474471603

Gear‑shaft press fits, key/key‑seat matching, torque‑tested gearboxes, kitting, laser‑marked traceability. Based on the same “components‑plus‑assembly” model used by leading platforms.

Flexible Logistics

Export‑compliant packaging, line‑side sequencing, tracked express or sea shipments, and customs paperwork—all managed by our team. Framework agreements and VMI programs keep your stores lean.

Scalable Supply Network

500 + audited partner workshops give us redundancy against outages and ensure capacity for spikes.

Performance Snapshot

(Infographic section)

On‑time delivery: 98.7%

Repeat‑order ratio: 92%

(Metrics audited internally; detailed dashboard available on request.)

FAQ

What tolerances can you hold? Standard ±0.05 mm, and tighter on request.

Which heat treatments? Induction, carburizing, nitriding, Q&T.

Gear quality classes? Up to DIN 6 / AGMA 11.

Minimum order size? From one prototype to 100,000 + pieces.

Sticky CTA Footer

“Get a Quote in 24 h” button + phone/WhatsApp icons for quick contact

Ready to take your industrial machinery project from drawing to production? Let us prove why engineers across the globe trust us for critical drive‑train components.