Private-Label OEM / ODM Manufacturing

For more than eight years, we have provided end-to-end OEM manufacturing services, and we now draw on 12 years of OEM/ODM experience in metal and plastic component production. From rapid quotation to global delivery, our plant integrates design, machining, and surface finishing so brand owners can launch private-label products faster than ever.

Two CTAs: “Request a Quote” | “Talk to an Engineer”

Services at a Glance

| Capability | Technical Highlight | Typical Deliverables |

| CNC Machining | Dimensional repeatability ±0.05 mm | Milled/turned housings, shafts, bushings |

| Casting & Forging | Open- & closed-die, gravity die | Valve bodies, brackets |

| Metal Stamping / Sheet-Metal | 25 t-200 t presses | Shields, spring clips |

| Plastic Injection-Mold Development | Single- & multi-cavity tooling | Molded plugs, caps |

| Metal & Plastic 3D Printing | SLS / SLM / FDM | Prototypes, jigs |

| Surface Treatment | Anodizing, nickel-plate, powder-coat | Class-A cosmetic parts |

| CAD / Pro-E Product Design | DFM + reverse engineering | Complete CAD packs |

| Screw-Machining | Up to Ø 38 mm bar | Precision fasteners |

Key Advantages (“Why Choose Us?”)

- ISO 9001:2000–certified quality system with incoming, in-process, and 50% final-lot inspection

- Quotation turnaround < 24 h and engineering counter-drawings in 1-3 days

- Prototype runs in 5 days for turning/milling parts

- Dedicated project engineer and single-point account management

- Broad material inventory (non-ferrous, steels, engineering plastics) for mixed-material assemblies

Such advantages let us deliver tightly-integrated ODM manufacturing solutions that cut your development cycle without losing traceability.

End-to-End Manufacturing Timeline

(Horizontal stepper)

RFQ to Quote — 24 h

Counter-Drawing — 1-3 days

Material Sourcing — 7 days if not in stock

Machining/Fabrication — 15-20 days

Testing & Inspection — 3 days

Packing & Export — 10 days

Total Lead Time: samples ≈ 5 days and mass production ≈ 40-45 days

Core Capabilities & Plant Equipment

Image Link: https://www.shutterstock.com/image-photo/minsk-belarus-2707-inside-wheel-tractor-1476741473

Machining Center Fleet: CNC milling, CNC turning, and dedicated screw machines handle prototype to mid-volume lots

Stamping Presses: 25-200 t mechanical lines for progressive-die work

In-House Surface Finishing: shot-blasting, vibratory deburring, anodizing line

Metrology Suite: Optical metal analyzer, Rockwell hardness tester, 2D measuring instrument—all calibration-logged

Engineering Software: Pro/ENGINEER & SolidWorks for concurrent engineering reviews

Material Portfolio

| Metals | Non-metals |

| Brass / Bronze / Copper | Nylon, POM, ABS, PP, PTFE |

| Aluminum & Aluminum Alloys | Rubber (NBR, EPDM, FPM, Silicone) |

| Free-cutting & Stainless Steels | Graphite |

| Zinc & Magnesium Alloys | — |

| Titanium Alloys | — |

Quality Assurance Workflow

Our QMS couples statistical-process-control sampling with 100% critical-dimension verification. Every shipment is accompanied by:

- Dimensional inspection report (CMM/2D instrument)

- Material certificate from in-house optical spectrometer

- Surface-finish & hardness records (Rockwell)

The result is a proven PPM performance accepted by tier-one valve, fluid-power, and electronic-housing clients.

Application Showcase

(Carousel of real parts with photos)

Valve Bodies (forged brass, CNC finish-machined)

Precision Bushings (free-cutting steel, Ra ≤ 1.6 µm)

Aluminum Heat-Sinks (die-cast + secondary machining)

Plastic Control Knobs (glass-filled ABS, texture VDI-24)

FAQs

What Data Should I Supply To Receive A Rapid Quotation?

Provide 2D drawings (PDF/DWG) or 3D models (STEP/IGES), material grade, surface finish, and target quantities. With this information, we can return a detailed quote (with any DFM notes) within 24 hours.

Can You Support Prototype Iterations Before Committing To Tooling?

Yes. We combine quick-turn CNC machining with metal and plastic 3D printing to ship functional prototypes in as little as five days for design validation prior to hard-tool release.

Do You Have A Minimum Order Quantity (MOQ)?

For most machining and additive projects, we can start at true prototype volumes. Tool-based operations, including stamping and injection molding, may have project-specific MOQ requirements, which we confirm on a case-by-case basis after reviewing your drawings.

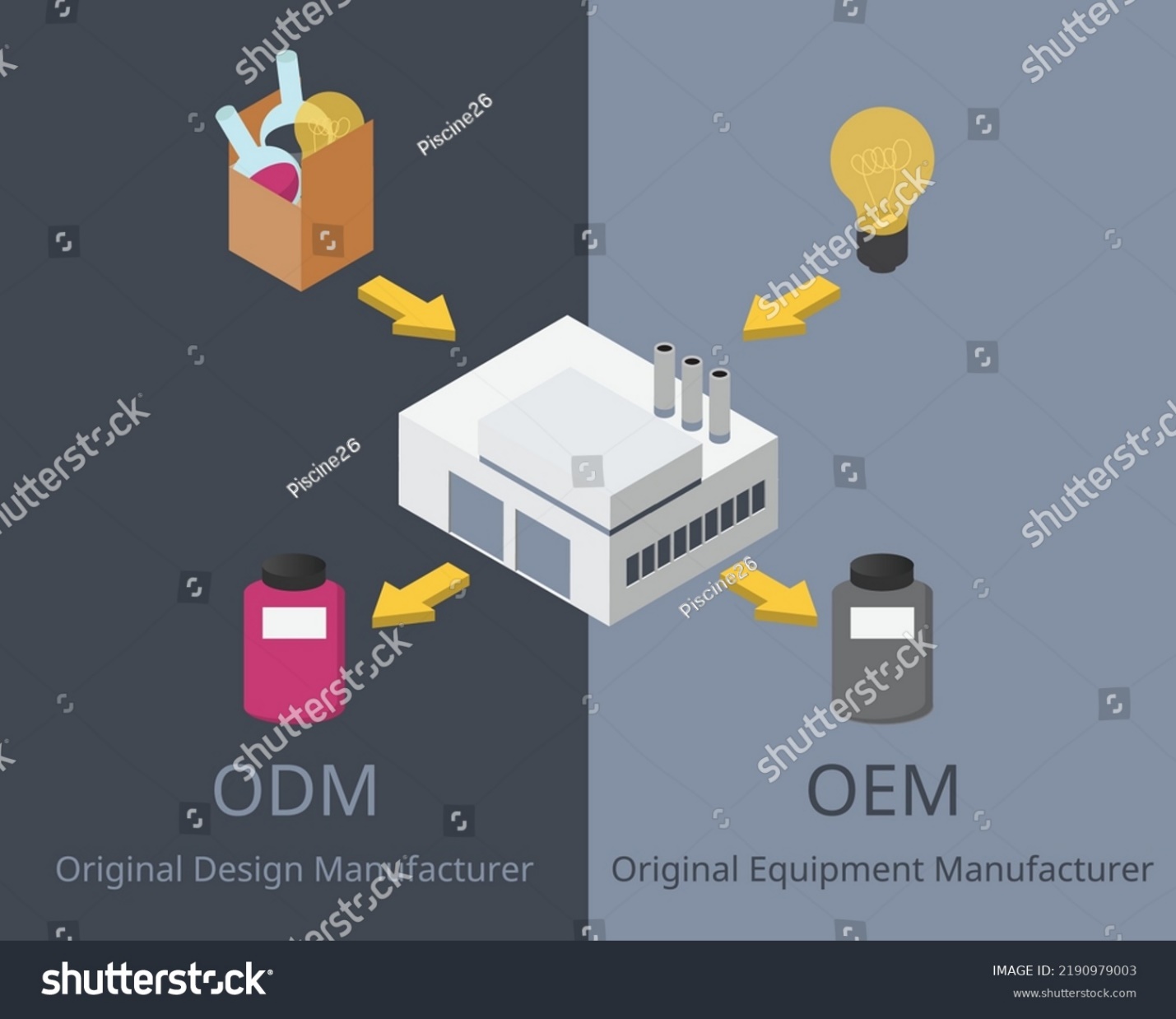

How Do OEM Manufacturing Services Differ From Your ODM Manufacturing Solutions?

OEM: You supply complete drawings and specifications, and we manufacture exactly to print.

ODM: We co-develop the product architecture, add manufacturability features, and deliver a turnkey private-label item ready for market.

Both routes use the same certified quality system, equipment, and material portfolio.

Ready to Start?

Get a formal quote in 24 hours—upload your STEP/IGES files or drawings, and our engineers will respond with a DFM review, costed BoM, and delivery schedule.