Stainless & Titanium Precision Parts for Medical & Laboratory Equipment

We are a laboratory equipment components manufacturer and precision partner for device OEMs, and we produce implant‑adjacent hardware, fluid‑handling fittings, miniature drive and actuation parts, and instrument mechanisms. Our vertically integrated mix of CNC machining medical devices components, forging/casting, stamping, surface treatments, and metal/plastic additive manufacturing supports fast prototypes and stable serial supply. ISO9001 quality controls, staged inspections, and in‑house material and hardness verification safeguard compliance, traceability, and repeatability through each batch.

Primary CTA: Request a Quote | Upload Drawing

Secondary CTA: Talk to a Manufacturing Engineer

Standard CNC Tolerance: ±0.05 mm (tighter after DFM review and capability alignment).

Fast Facts / USPs / Badges

- ISO9001:2000 certified quality system with incoming material verification, in‑process QC, and elevated final‑inspection sampling.

- Standard CNC Tolerance: ±0.05 mm across turning & milling, and project‑specific tolerances validated during DFM.

- Materials Mastered: Titanium alloys, stainless steels, aluminum, brass/bronze/copper, free‑cutting/carbon steels, zinc & magnesium alloys, engineering plastics (Nylon, POM, ABS, PP, PTFE), and elastomers (NBR/EPDM/FPM/Silicone), graphite.

- Sample parts in ~5 days for turning/milling.

- Typical Bulk Production Lead Time: 40-45 days total from quotation to packing, along with interim milestones (drawings, procurement, machining, test, pack) published at award.

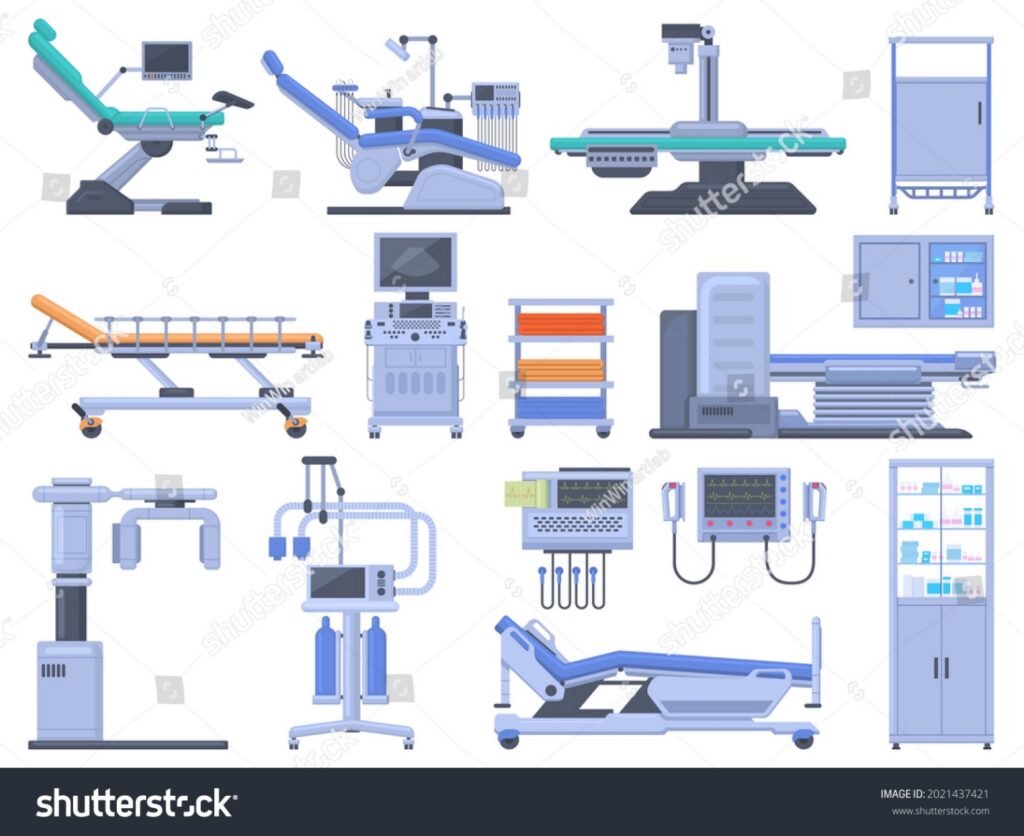

Where We Fit In Medical & Lab

Image Link: https://www.shutterstock.com/image-vector/healthcare-hospital-clinic-medical-diagnostic-equipment-2021437421

Surgical & Device Hardware: Precision turned/milled stainless and titanium fasteners, shafts, sleeves, collars, spacers, hubs, housings, and custom clamp/lock components.

Fluid & Valve Components: Bodies, bonnets, seats, stems, plungers, ferrules, union nuts, and ported manifolds for dosing, wash, rinse, and sterilization circuits.

Laboratory Mechanisms & Fixtures: Linear/rotary shafts, micro‑geared hubs, brackets, carriers, and sensor brackets in SS/Ti/Al and technical polymers with low‑particulate finishes.

Mechatronics & Imaging Assemblies: Mounting plates, heat‑sink frames, RF‑shielded covers, and precision bores/bosses for bearing seats and encoder pick‑ups.

Prototype → Pilot → Serial: We combine CNC turning/milling/screw machining with forging/casting, stamping, injection‑mold tooling, and both metal and plastic 3D printing to sustain cost, weight, and speed targets from first article through ramp.

Materials & Specifications

Image Link: https://www.shutterstock.com/image-photo/orthopedic-surgical-instrument-prepare-surgery-fracture-2293918807

Titanium Alloys (CNC & AM): High strength‑to‑weight ratio and corrosion resistance for implant‑adjacent brackets, housings, and load‑bearing linkages. Available via CNC milling/turning and metal AM (Ti alloys) for weight‑optimized lattices or internal channels.

Stainless Steels: Austenitic and martensitic grades machined to tight positional and geometric tolerances. Use cases include valve internals, flow hardware, structural brackets, and precision threaded or flanged interfaces.

Additional Metals: Aluminum for light, thermally conductive frames, brass/bronze/copper for corrosion‑resistant, non‑sparking fittings, and excellent machinability, free‑cutting & carbon steels for strength‑critical mechanisms, and zinc & magnesium alloys for lightweight housings.

Engineering Polymers & Elastomers: Nylon, POM, ABS, PP, PTFE for chemically compatible bushings, manifolds, covers, and fixtures, NBR/EPDM/FPM/Silicone for seals and vibration isolation, and graphite for high‑temperature or lubricious applications.

Baseline Machining Capability: ±0.05 mm, tighter GD&T (true position, circularity, flatness, perpendicularity, profile) available after DFM and process proof. Surface finish, deburr standards, passivation/electropolishing, and media characteristics are set per drawing/spec.

Processes & Value‑Add

Machining

- CNC turning (incl. bar‑feed and screw machining) for high‑repeatability small diameters and miniature components.

- CNC milling for multi‑face, multi‑op parts with critical bores, pockets, and thin‑wall sections.

Forming & Casting

- Closed/open‑die forging and precision casting for net‑shape or near‑net blanks to decrease machining time and material waste.

- Stamping for repeatable sheet/strip features, spring elements, and low‑unit‑cost brackets.

Additive Manufacturing

- Stainless, aluminum, titanium alloys for lightweight, complex channels and consolidated assemblies.

- ABS, Nylon, POM for rapid fixtures, housings, and pilot‑run functional parts.

Tooling & Molds

- Plastic injection mold development to support overmolded or hybrid metal‑plastic assemblies.

Design For Manufacturability (DFM)

- CAD/Pro‑E design support. Counter drawings released within 1-3 days from the RFQ. We evaluate tolerances, datum schemes, wall thickness, fillets/chamfers, thread standards, tool access, workholding, and inspection strategy to balance risk, cycle time, and cost.

Quality Assurance for Regulated Parts

Certified System: ISO9001:2000 with documented procedures for incoming material inspection, in‑process checks, and elevated final inspection sampling at 50% of items prior to packing. Sampling plans can be adapted to customer AQL.

Inspection & Test Equipment:

- Optical metal analysis for incoming alloy verification and heat‑to‑cert correlation.

- Rockwell hardness testing to verify heat treatment and finishing impact.

- 2D measuring instrument for dimensional verification, feature‑to‑feature relationships, and small‑feature metrology.

Documentation: Material analysis results, hardness data, and dimensional inspection summaries can be recorded and supplied when specified at RFQ/PO.

Traceability: Heat/batch records maintained through production, inspection, and packing, alongside lot segregation by traveler and packaging ID.

Typical Timeline & Lead Times

Visual timeline or table:

Quotation: within 24 hours for standard materials.

Counter Drawings / DFM: 1-3 days.

Material Procurement: ~7 days if not in stock.

Machining: 15-20 days.

Testing & Inspection: 3 days.

Packing: 10 days.

Bulk Production Lead Time: 40–45 days total.

Samples: turning/milling samples in about 5 days.

Final CTA

Ready to machine your stainless & titanium components?

Request a Quote | Upload Drawing | Schedule an Engineering Call