Tooling & Fixtures

CAD‑Perfect Jigs & Fixtures Design Delivered Fast

12+ years OEM/ODM experience | ± 0.05 mm standard tolerance | ISO 9001‑2000 certified QC

Get a Tested Tool‑Set Quote Back Within 24 H

Why Choose Our Custom Fixturing and Tooling Services

Three‑column benefit grid:

Audited Supply Chain & ISO‑Driven Inspections keep every gauge and jig traceable from raw stock to final CMM report.

End‑To‑End CAD/Pro‑E Workflow – our engineering team takes your STEP/DWG, runs DFM, and releases tooling drawings ready for in‑house machining.

Predictable Lead Times – quote < 24 h, drawings 1‑3 d, machining 15‑20 d, full tool set in 40‑45 d

Technical Data at a Glance

| Parameter | In‑House Capability |

| Standard dimensional accuracy | ± 0.05 mm |

| Max tool envelope | 1,000 × 600 × 500 mm (larger upon request) |

| Supported CAD formats | STEP, STP, IGES, DWG, DXF, Pro‑e/Creo native |

| Typical surface roughness | Ra 0.8 µm machined / Ra 0.4 µm ground |

What We Do

Jigs and fixtures designed for machining, welding, inspection, and assembly cells

- CNC‑milled aluminum, steel, or polymer fixtures with hardened steel wear inserts

- Injection‑mold, die‑set, and stamping tooling development

- Rapid 3D‑printed soft tooling for pilot runs

All services are delivered under the same roof for unified feedback between design and shop‑floor teams.

Materials & Finishes

Two‑column list:

Metals

Brass/Bronze/Copper, Aluminum, Free‑cutting & Stainless Steels, Zinc / Magnesium, Titanium

Non‑Metals

Nylon, POM, ABS, PP, PTFE, Technical Rubber (NBR/EPDM/FPM/Silicone), Graphite

Optional surface treatments (anodizing, electroless nickel, hard‑chrome, black oxide) tie in with our Surface Treatment service page.

Typical Lead Times

| Stage | Calendar days |

| Quotation | < 1 |

| Counter‑drawing | 1-3 |

| Material sourcing | 7 |

| CNC / EDM / grinding | 15-20 |

| QC & test fit | 3 |

| Secure packing & export | 10 |

Total 40-45 days for serial tooling, and 5 days for prototype fixtures. Express slots are available on request.

Quality Assurance You Can Audit

ISO 9001‑2000 system & stage‑gate inspections

Lab Equipment

- Optical spectrometer for alloy verification

- Rockwell hardness tester for insert hardness mapping

- 2D measuring instrument for first‑article reports

Customers receive a full dimensional report and material certificate with every shipment.

From CAD to Calibrated Fixture in 3 Steps

Upload & Specify – send us your drawing/3D model.

In‑Process QC – we machine, heat‑treat, and verify every critical surface.

Receive Tested Tooling – fixtures arrive pre‑set, labeled, and ready for your line.

FAQs

What Tolerance Can You Guarantee On Bore Gauges?

We hold ± 0.02 mm on critical gauging features, and the general tolerance is ± 0.05 mm.

Which File Types Are Best For Jigs And Fixtures Design?

STEP (.stp), IGES (.igs), or native Creo/Pro‑e are ideal. Include 2D PDFs for GD&T.

Can You Help Choose Fixture Materials?

Yes—our engineers reference hardness, weight, and corrosion constraints against the material palette above.

Do You Offer Repeat‑Order Discounts?

Framework agreements can lock pricing for 12 months while ensuring capacity.

What about IP Protection?

We sign mutual NDAs and store files on encrypted servers.

Related Production Methods

Horizontal card links:

CNC Machining | Stamping | Plastic Injection | 3D Printing

Ready to Start?

Large “Request a Tooling Quote” button

Secure, fast, and backed by our ISO‑certified custom fixturing and tooling services expertise.

What We Do

Image Link: https://www.shutterstock.com/image-photo/iron-casting-pipes-were-clamped-on-1703349388

• Jigs and fixtures designed for machining, welding, inspection, and assembly cells

• CNC‑milled aluminum, steel, or polymer fixtures with hardened steel wear inserts

• Injection‑mold, die‑set, and stamping tooling development

• Rapid 3D‑printed soft tooling for pilot runs

All services are delivered under the same roof for unified feedback between design and shop‑floor teams.

Materials & Finishes

Two‑column list:

Metals

Brass/Bronze/Copper, Aluminum, Free‑cutting & Stainless Steels, Zinc / Magnesium, Titanium

Non‑Metals

Nylon, POM, ABS, PP, PTFE, Technical Rubber (NBR/EPDM/FPM/Silicone), Graphite

Optional surface treatments (anodizing, electroless nickel, hard‑chrome, black oxide) tie in with our Surface Treatment service page.

Typical Lead Times

Stage Calendar days

Quotation < 1

Counter drawing 1-3

Material sourcing 7

CNC / EDM / grinding 15-20

QC & test fit 3

Secure packing & export 10

Total 40-45 days for serial tooling, and 5 days for prototype fixtures. Express slots are available on request.

Quality Assurance You Can Audit

ISO 9001‑2000 system & stage‑gate inspections

Lab Equipment

• Optical spectrometer for alloy verification

• Rockwell hardness tester for insert hardness mapping

• 2D measuring instrument for first‑article reports

Customers receive a full dimensional report and material certificate with every shipment.

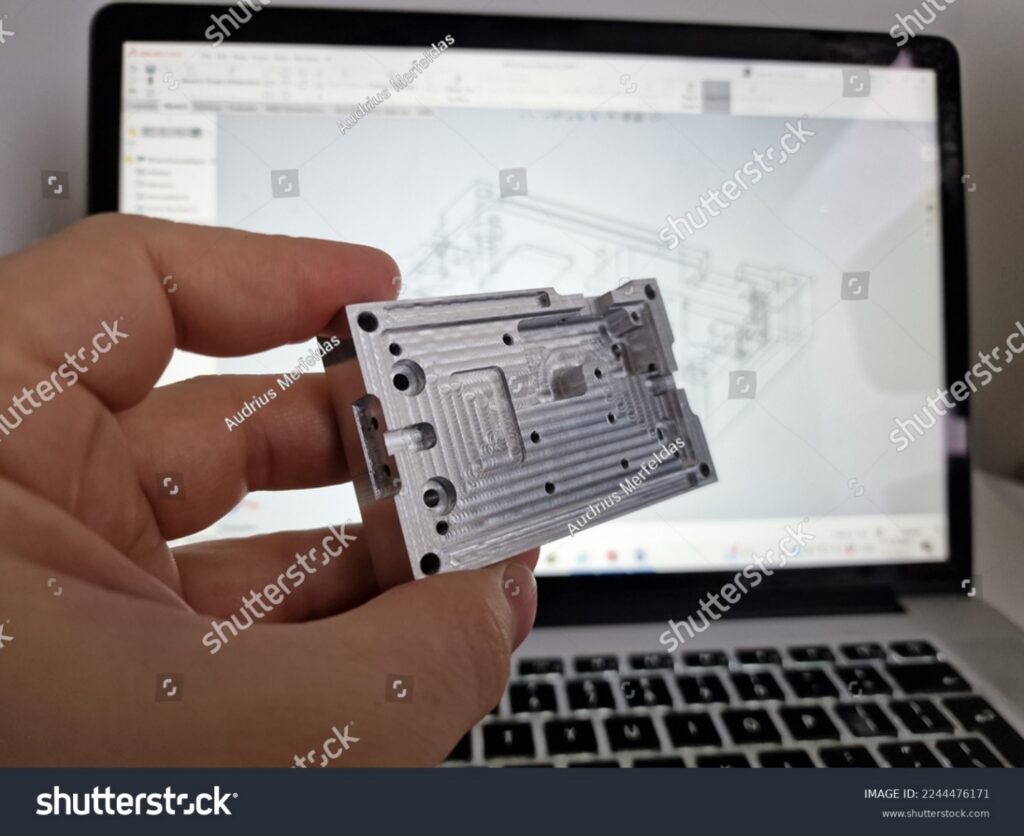

From CAD to Calibrated Fixture in 3 Steps

Image Link: https://www.shutterstock.com/image-photo/mechanical-engineer-hand-holding-cnc-milled-2244476171

Upload & Specify – send us your drawing/3D model.

In‑Process QC – we machine, heat‑treat, and verify every critical surface.

Receive Tested Tooling – fixtures arrive pre‑set, labeled, and ready for your line.

FAQs

What Tolerance Can You Guarantee On Bore Gauges?

We hold ± 0.02 mm on critical gauging features, and the general tolerance is ± 0.05 mm.

Which File Types Are Best For Jigs And Fixtures Design?

STEP (.stp), IGES (.igs), or native Creo/Pro‑e are ideal. Include 2D PDFs for GD&T.

Can You Help Choose Fixture Materials?

Yes—our engineers reference hardness, weight, and corrosion constraints against the material palette above.

Do You Offer Repeat‑Order Discounts?

Framework agreements can lock pricing for 12 months while ensuring capacity.

What about IP Protection?

We sign mutual NDAs and store files on encrypted servers.

Related Production Methods

Horizontal card links:

CNC Machining | Stamping | Plastic Injection | 3D Printing

Ready to Start?

Large “Request a Tooling Quote” button

Secure, fast, and backed by our ISO‑certified custom fixturing and tooling services expertise.