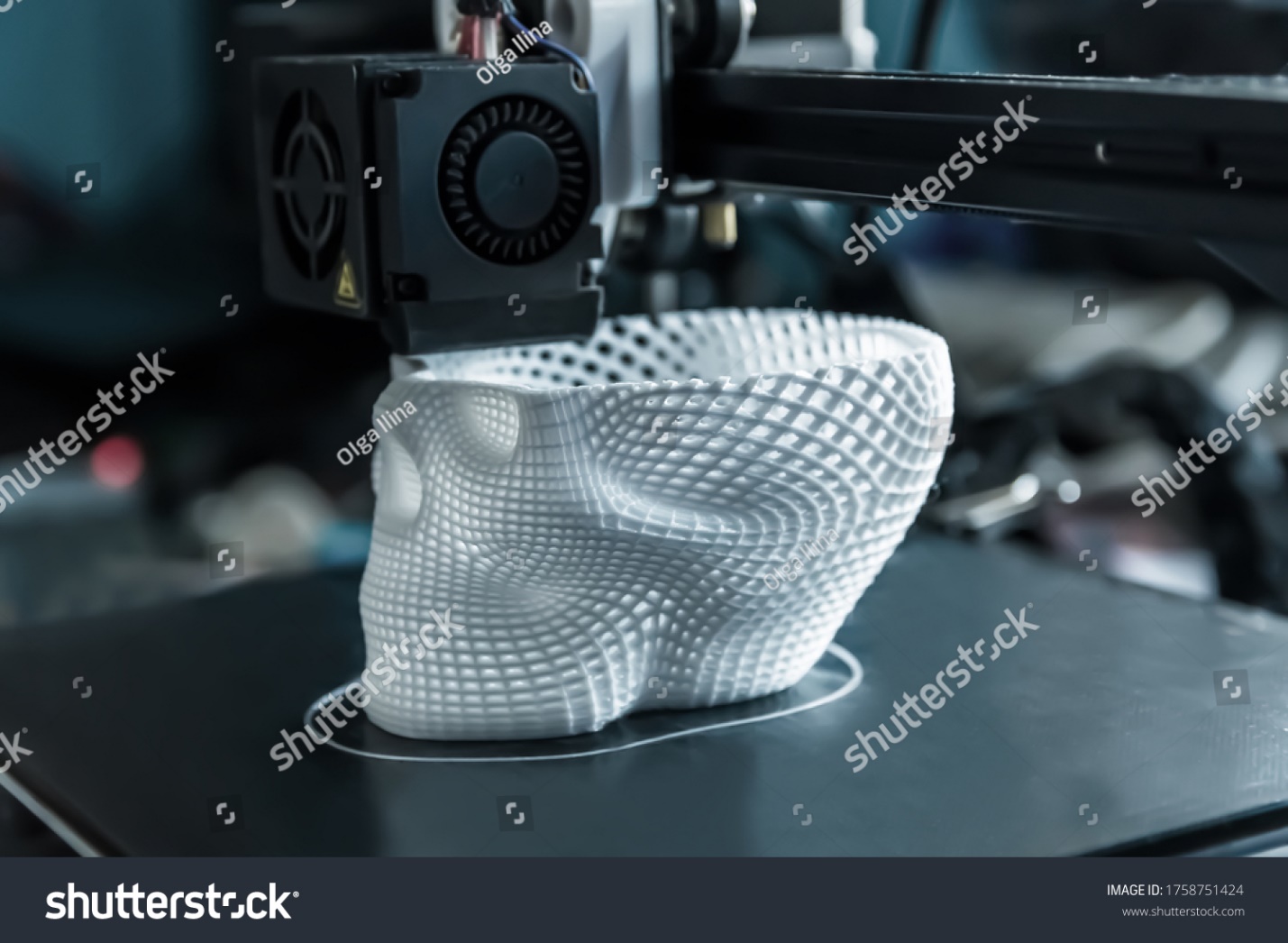

Rapid prototyping services that move as fast as your ideas.

Upload your CAD file today and receive functional, production-grade parts in as little as five working days. Our quick-turn prototyping workflow combines in-house 3D printing and precision CNC machining held to ±0.05 mm.

Why Engineers Choose Us

- Quote returned within 24 h for standard materials

- Metal & plastic 3D-printing line plus quick-change CNC mills/turns

- ISO 9001-2000 quality gate at every stage

CTA: Upload CAD → Get My Quote

Why Choose Us

| Advantage | Detail |

| Experience | 8 years OEM for metal and plastic parts, and 12 years dedicated metal OEM/ODM |

| Capacity on demand | Parallel CNC cells, multi-material printers, and a vetted supplier network keep lead-times predictable even during spikes. |

| Personal engineering support | A dedicated project engineer reviews DFM, issues a manufacturability report, and stays with your order until delivery. |

| From idea to production | Same shop floor handles prototypes, pilot runs, and full batches—no re-qualification needed. |

Capabilities at a Glance

CNC Machining (Milling, Turning) — ±0.05 mm standard tolerance

Industrial 3D Printing — metals or plastics, direct-from-CAD

Forging / Casting, Stamping, Surface Finishing, CAD / Pro-E Design Assist — end-to-end part realization

Supported Materials

Metals

Brass, bronze, copper, aluminum, free-cutting steel, stainless steel, zinc & magnesium alloys, titanium

Plastics & Elastomers

Nylon, POM, ABS, PP, PTFE, NBR, EPDM, FPM, silicone, graphite composites

Printable Materials

Direct laser or extrusion for Stainless-Steel, Al, Ti alloys, ABS, Nylon, POM

Lead-Time Options

| Stage | Typical duration |

| Quote & DFM feedback | ≤ 24 h |

| Prototype manufacturing (CNC or 3DP) | 5 working days for turning/milling prototypes |

| Production batch | 15-20 days machining + QC + packing, and 40-45 days complete for bulk |

Lead-times assume stocked materials and standard finishes, as well as expedited slots available for critical quick-turn prototyping projects.

Quality Assurance

ISO 9001-2000 Certified Plant — incoming, in-process, and 50% final-lot inspection

Metallurgical Verification — optical metal analysis for alloy confirmation on every heat lot

Mechanical Integrity — Rockwell hardness tests logged per batch

Dimensional Fidelity — high-resolution 2D vision measuring instrument checks critical features

How Our Rapid Prototyping Works (3 Steps)

1. Upload & Specify: Secure portal accepts STEP, IGES, Parasolid, and native files. DFM report with pricing lands in your inbox in ≤ 24 h.

2. Manufacture & Validate: Parts are produced via CNC or industrial AM, and every job passes ISO-based first-article and in-process checkpoints.

3. Deliver & Iterate: Certified parts ship worldwide in as little as five days and let your team test, learn, and re-spin faster.

Design Resources

CNC Tolerance Cheat-Sheet (PDF) — nominal vs. achievable fits

3D-Printing Design Guide — wall-thickness and support strategies per material

Surface-Finish Gallery — anodizing, hard-coat, bead-blast, electroless Ni, laser marking

Material Selector Poster — compare strength, weight, and cost across our stocked alloys and polymers

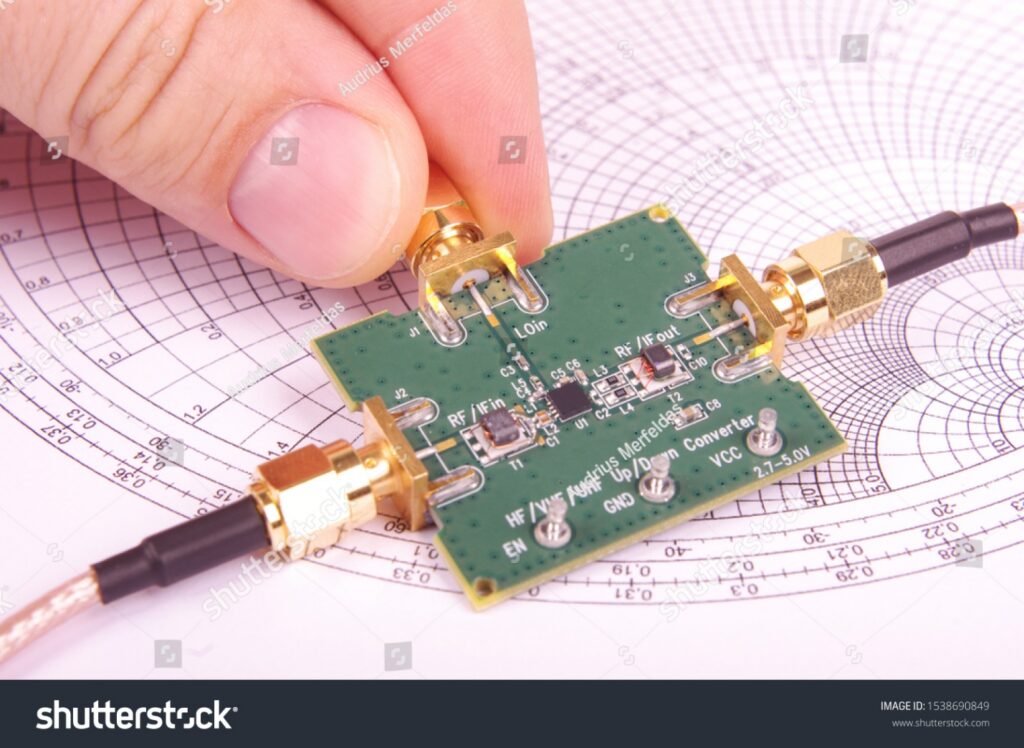

Typical Use-Cases & Industries

Image Link: https://www.shutterstock.com/image-photo/radio-frequency-engineer-inspect-microwave-mixer-1538690849

- Functional R-&-D prototypes

- Pilot-run components for medical, robotics, and consumer electronics

- Jigs, fixtures, and test rigs for automation cells

- Lightweight structural parts for UAV and mobility platforms

Our quick-turn prototyping shop has delivered thousands of such parts to engineers worldwide.

FAQs

What Maximum Part Size Can You Handle?

Up to 650 x 400 x 350 mm in a single setup, and larger builds can be section-printed and joined.

Which CAD Formats Do You Accept?

STEP, IGES, Parasolid, SolidWorks, Inventor, Catia, NX.

Can You Sign An NDA?

Yes—standard MNDA or yours, executed before file upload.

Do You Certify Material And Inspection Data?

Material Certificates + CMM/vision reports are supplied on request.

Ready to Prototype?

Need metal or plastic parts yesterday? Upload your CAD now and let our rapid prototyping services turn your concept into reality with industry-leading quick-turn prototyping speed.